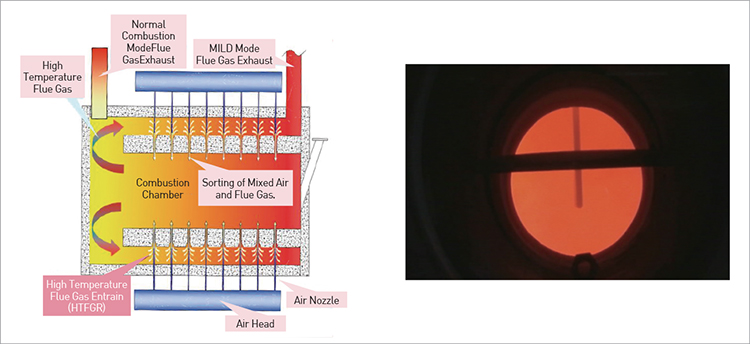

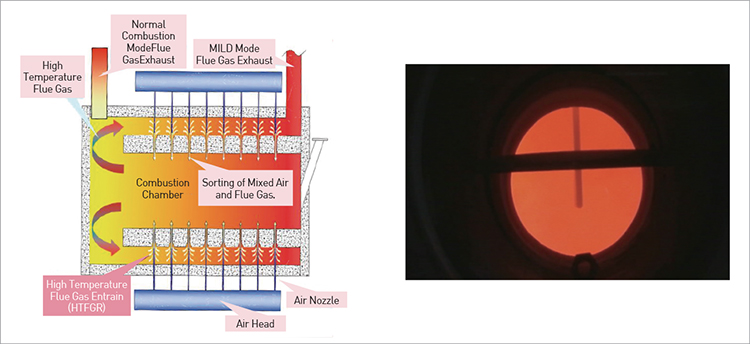

Technology of mixing high-temperature flue gas with combustion air by nozzle of Coanda effect to lower the oxygen content while heating it to a higher temperature to make MILD combustion for superlow-NOx emission

Client / Market

- Combustor/industrial furnace/incinerator/thermal power generation

Necessity of this Technology

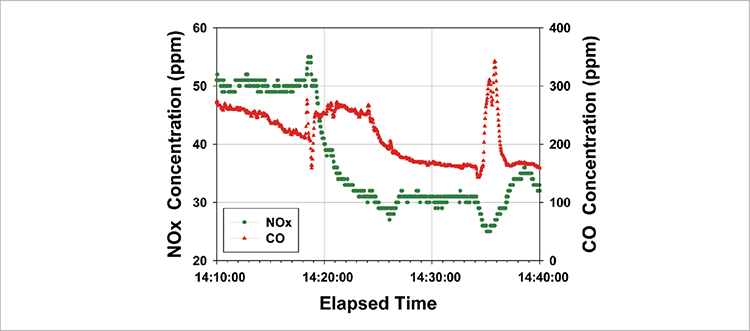

- An air nozzle combined with the Venturi type tube was used to mix high temperature combustion gas with air jet to reduce carbon monoxide (CO) and nitrogen oxides (NOx) simultaneously.

- However, for this method, the center of the air nozzle and the Venturi tube needs to be combined in a straight line, and the Venturi tube has to be of a certain length to generate negative pressure to induce high-temperature combustion gas, and because of this, the combustor wall has to be thicker.

- When the combustor wall becomes thicker, the width of the passage where hightemperature combustion gas flow and the width of the entire combustor increases, which means the area for installation has to be increased. And this leads to a higher cost.

Technical Differentiation

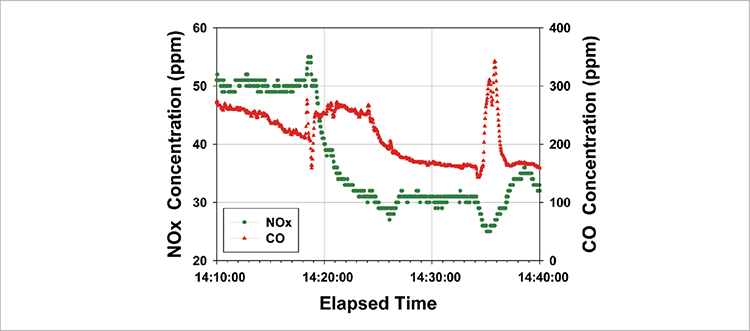

- By mixing high-temperature combustion gas withcombustion airjet by a simple structure without increasing the wall thickness, reduction of NOx and CO becomes easier. With the NOx reduction effect of 80% for gas fuel and 40% for solid fuel, the installation and operation cost of the post treatment facility can be saved.

- No previous technology case of using a nozzle of Coanda effect for recirculation of high-temperature combustion gas was found.

Excellence of Technology

- The NOx and CO reduction effect in the combustion furnace with the air nozzle and Venturi tube has been proven, and the nozzle with Coanda effect was produced, and it was confirmed that the induction of combustion gas was effectively done.

- MILD combustion-applied incinerator and pellet heat technology transfer for commercialization is in the process.

- As the result of the experiment with MILD combustion using solid fuel, the NOx concentration was proven to have reduced by 40%.

- Compared to conventional combustion, the excess air ratio can be reduced significantly to within 10% that it can reduce thermal loss and improve thermal use efficiency.

- By decreasing the peak temperature inside the combustor, ash melting and adherence is prevented to reduce damage of the incinerator wall and repair time.

Current Intellectual Property Right Status

PATENT

- Low Pollutant Emission Combustion Using High-temperature FGR (KR1133434)

- Low Pollutant Emission Combustion Using High-temperature FGR and Nozzle of Coanda Effect (KR1289411)

- Super Low-NOx Emission Combustion Apparatus Using Coanda Effect (KR1320406, PCT/KR2013/011796)

- Pellet Combustion Device and Method for Low-emission (KR1471636)

- Super-low NOx Emission Combustion Apparatus Using Coanda Effect (KR1453859)

KNOW-HOW

- Optimal Coanda nozzle design technology to increase the FGR rate

- O ptimal FGR Coanda nozzle arrangement technology to maximize NOx reduction effect

- Horizontal and vertical combustion furnace design technology for super-low NOx emission during combustion

|