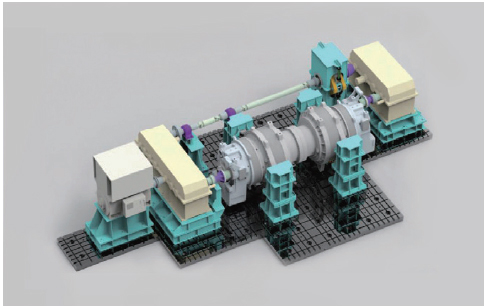

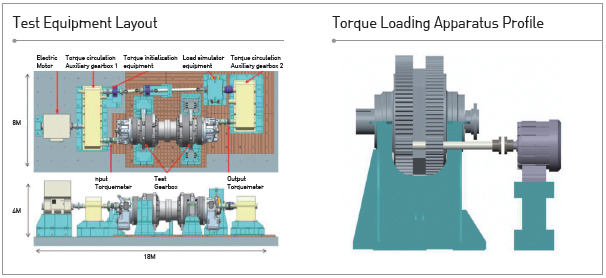

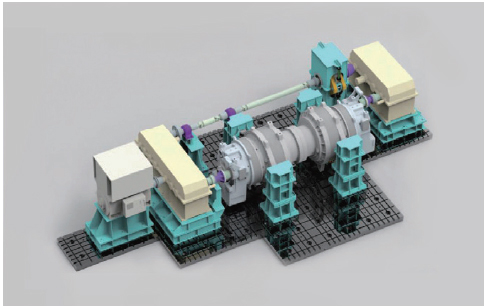

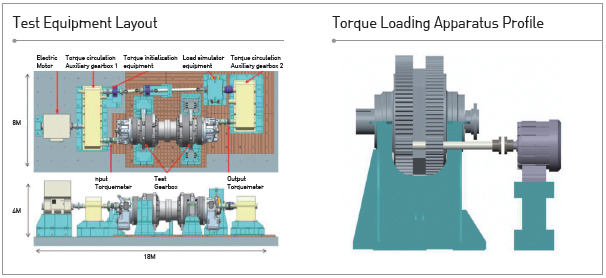

Test equipment for performance and durability assessment with the

variable torque and speed conditions for a large gearbox up to 5.5 MW

Client / Market

- Large gear box manufacturer (Step-up gearbox for wind turbine, Reducer gearbox

for ship)

Necessity of this Technology

- There is a need for a test equipment for large gearbox that could vary the initial

speed and torque.

- For R&D and commercialization of large gearbox, the quality needs to be certified

or data needs to be secured through performance and durability assessment, but

establishment of test equipment for large gearbox in Korea is inadequate, and the

test is mostly performed by foreign company or institution.

- The mechanical type large gearbox taster is inconvenient to adjust the torque

through multiple trial and error as the tester cannot accurately apply the set initial

torque to the gearbox or the tester applies the torque with the manual apparatus

without setting an initial torque.

- Since the tester manually applies the torque to the axis to increase the torque

applied to the gear box, the speed and torque cannot be changed during the test.

- An apparatus and a test apparatus that could perform the test under a realistic

condition are in need.

Technical Differentiation

- It installs the epicyclic gearbox for torque application on the torsion axis that

increases the torque applied to the gearbox and rotates the ring gear of the epicyclic

gearbox to the actuator or installs a torque control motor to accurately increase the

torque applied to the gearbox. The performance/durability assessment can be done

under various conditions.

- By setting the torque with the automatic torque application apparatus (actuator or

torque control motor) and the control system, the exact torque can be applied to the

gearbox, and it reduces the test time.

- With various gear box tests, a separate epicyclic gearbox, automatic torque

application apparatus and control system can be installed to realize initial torque

and variable torque instead of the method of applying a load to the torque arm of the

epicyclic gearbox to generate torque.

Excellence of Technology

- A separate epicyclic gearbox, automatic torque application apparatus and control

system can be installed each to apply the exact initial torque, and desired torque can be

realized without stopping during the performance and durability test of a large gearbox.

- Gearbox test and fatigue test expert, and 10 research engineers with the sum of

their experience in gearbox performance test and fatigue analysis adding up to 85 years

participated in this research.

CURRENT INTELLECTUAL PROPERTY RIGHT STATUS

PATENT

- Gearbox Tester Having Variable Torque Function and Variable Torque Applied

Method (KR1109540)

- Setting Apparatus of Initial Torque for Gearbox Tester and Setting method of Initial

Torque (KR1099695)

- Torque Loading Device and Torque Control System (KR1380210)

|