List of KIMM TechnologiesBusan Machinery Research Center

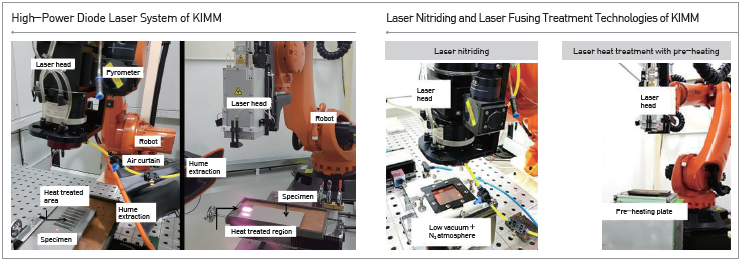

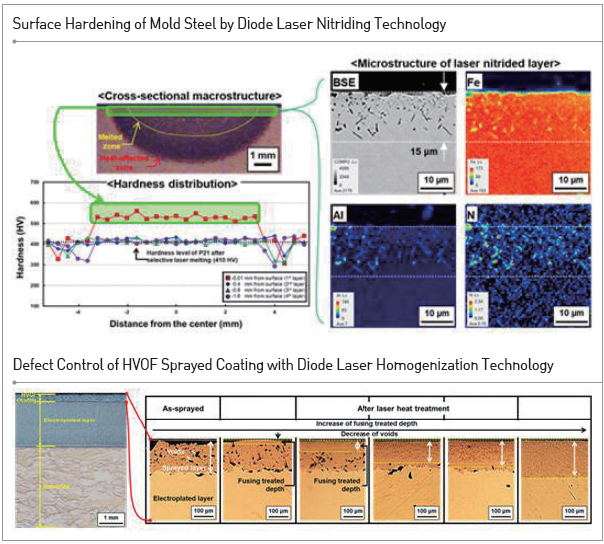

Surface Hardening and Homogenization Technology for Metallic Materials Using High–power Diode Lasers

| Division | Busan Machinery Research Center > Department of Industrial Laser Technology |

|---|---|

| Name | Dr. Su Jin Lee |

| Department | Laser Industrial Technology Research Group |

| Tel | +82 - 51 - 310 - 8133 |

| leesj@kimm.re.kr | |

| Attachment | Download 161_Surface_Hardening_and_Homogenization_Technology_for_Metallic_Materials_Using_High_power_Diode_Lasers.pdf (0.6 KB) |

Surface hardening and homogenization technology of metallic materials with high-power diode lasers (beam dimension: 20-2500 mm2)Numerical computation and real-time control technology of optimum laser heat treatment temperature

Client / Market

Necessity of this Technology

Technical Differentiation

Excellence of Technology

KNOW-HOW

|