Continuous electroless nanoparticle manufacturing technology extracting various metal or CIGS metal particles used for thin film solar cell or general nano metal particles using metal salt

Client / Market

- Metal nano particle manufacturer, metal powder manufacturer, CIGS thin film solar cell manufacturer

Necessity of this Technology

- Metal dry extraction technology, high capacity production process, economic feasibility verification, and CIGS production uses nano ink manufacturing technology.

- CIGS thin film solar cell is manufactured with vacuum sputtering process for CIGS particle fusion, however, this process is complex, costs a lot, and is difficult to control the fusion rate of the material.

- This technology uses ink printing method for CIGS metal nanoparticle manufacturing for simple CIGS thin film manufacturing.

- Low cost, simple process of metal nanoparticle generation including CIGS metal nano particle is needed.

Technical Differentiation

- Nanoparticle can be generated continuously with metal salt at a low cost.

- With the ink printing method using CIGS nanoparticle, material for thin film production is saved and the process is cheap.

- By extracting multiple metals at once, the process is easy, and the productivity is high.

- In the copper particle generating test using copper salt, particles in size of several hundred ㎚ to few dozen μm were generated.

- Existing CIGS thin film solar cell manufacturing methods include co-evaporation, sputtering, and MOCVD, but they require expensive vacuum sputtering process or RTP process as mandatory. Also, these processes are expensive and have difficulty in controlling the CIGS fusion rate.

- CIGS ink printing method makes ink with CIGS nanoparticles and prints on the substrate with the printing technique, and this is much simpler compared to the sputtering method. This method barely wastes any material, and advanced countries have been investing heavily in this process.

- Existing metal nanoparticle generating methods include mechanical mill method, solvothermal, solvochemical methods, but their economic feasibility is low or they require high temperature and high pressure.

Excellence of Technology

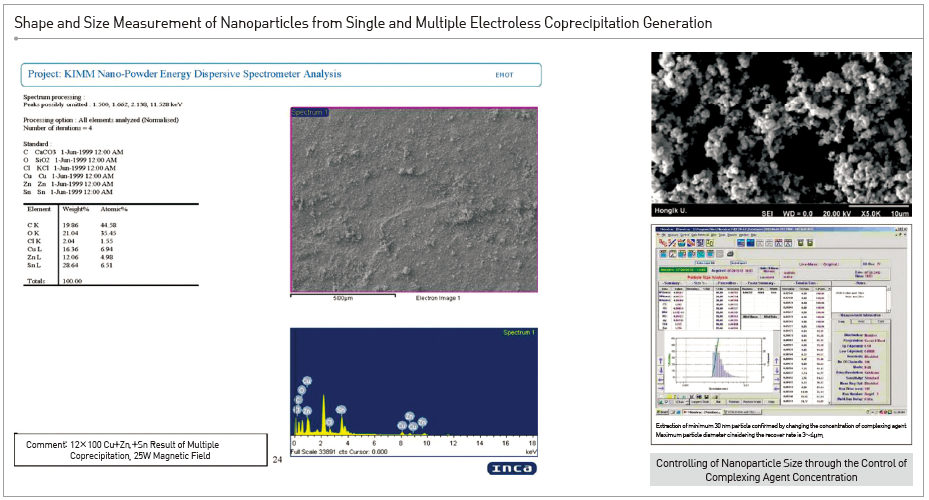

- The method uses hydrazine (N2H4) to return metal salt of the metal subject for extraction (e.g. Cu, In, Ga, Se Chloride), and it can achieve single or multiple extractions.

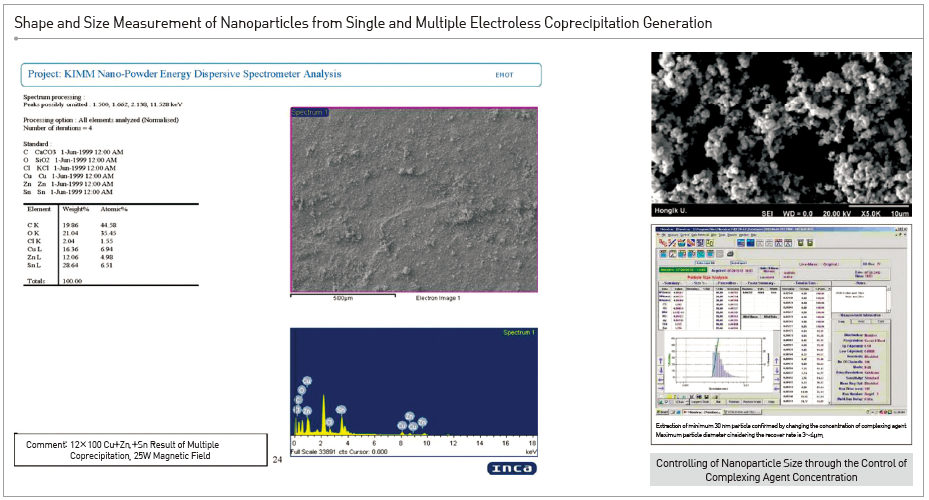

- By adding complexing agent, specific amount of metal salt reaction is maintained, and the particles extracted from the reactor and overflown are collected; and the Cu nano particles photographed with the SEM.

- The particles are dried in vacuum condition, go through gold coating (sputtering) and then photographed with the SEM.

- It was confirmed that the nanoparticle size was reduced and became consistent.

Current Intellectual Property Right Status

PATENT

- Continuous Electroless Coprecipitation Nanoparticle Manufacturing Device Using Electromagnetic Field (KR1393542)

- Continuous Electroless Coprecipitation Nanoparticle Manufacturing Device (KR1513927)

KNOW-HOW

- Possible to apply new concept agitator technology and magnetophoretic technology

- Possible to manufacture metal nano powder for 3D printer material

- Possible to improve purity in metal nanoparticle manufacturing

|