Organic Rankine cycle generation system for fully recycling of engine coolant heat and exhaust heat

Client / Market

- Waste heat power generation for automobile, ship, and power generation engine

Necessity of this Technology

- Single-loop type ORC system suggested for engine waste heat recovery has a simpler equipment composition and is more economically feasible than the dualloop method. However, it cannot effectively use 100% of the engine’s coolant heat and exhaust heat at the same time, that the ORC output from the same engine waste heat is only about 70% compared to the dual-loop method.

Technical Differentiation

- Fully uses both coolant heat and exhaust heat from the engine.

- Achieves a cycle efficiency of 9.5%

- By making the refrigerant evaporation temperature of No.1 heat exchanger slightly lower than the engine coolant, the engine coolant heat of No. 1 heat exchanger can be used as evaporation heat 100% when the refrigerant is pre-heated in No. 1 regenerative heat exchanger.

- By using up to 100% of the engine coolant heat as evaporation heat, the engine waste heat recovery apparatus can reduce the temperature difference between the heat source and the working fluid in the process of the refrigerant evaporating in No. 1 heat exchanger, that the irreversible loss that occur from the temperature difference occurring in the existing process of evaporation by the heat from-engine exhaust gas can be reduced.

- With the novel heat exchange arrangement and ORC system optimization, the system performance (5.7 kW) is close or even exceeds that of existing dual-loop method under the same condition and assumptions while the system is as simple as the single-loop method.

Excellence of Technology

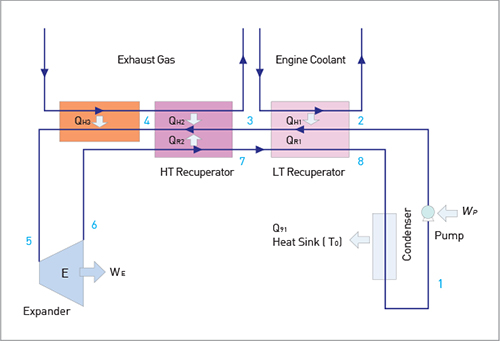

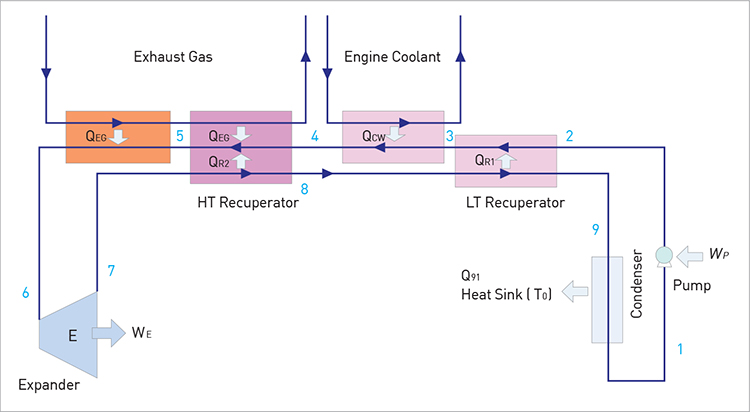

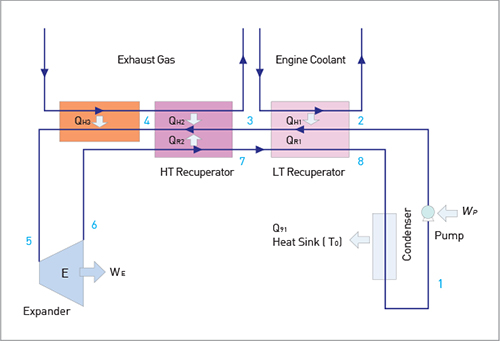

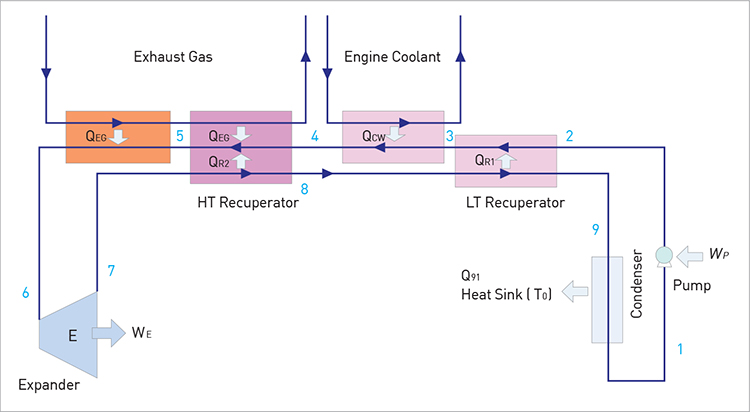

- The regenerative heat exchanger is composed of the high temperature (HT) recuperator and low temperature (LT) recuperator, and the liquid refrigerant heated with the LT recuperator evaporates with the engine coolant heat and then superheated through the HT recuperator, which is then heated to the maximum temperature with the engine exhaust heat and supplied to the expander.

- The evaporation temperature for liquid refrigerant can be set a bit lower than the engine coolant to use 100% of the engine coolant heat as the evaporation heat even when the liquid refrigerant is heated with the regenerative heat exchanger. Since the evaporation temperature is limited with the engine coolant temperature, there is a downside where the cycle efficiency cannot be increased, but since the temperature difference between the heat source and working fluid in the evaporation process is very small, there is a benefit of reducing the irreversible loss from the temperature difference in the existing evaporation process by engine exhaust heat.

- Presented papers at international scholastic society meetings(“Highly efficient single-loop organic Rankine cycle for engine waste heat recovery” presented at Conference on Sustainable Development of Energy, Water and Environmental Systems (SDEWES 2014))

- Published SCI(E) papers(“Highly efficient single-loop organic Rankine cycle for engine waste heat recovery”(Energies, 2014.10 submitted))

Current Intellectual Property Right Status

PATENT

- Engine Waste Heat Recovery Apparatus (KR2013-0040324)

|